![]()

Problem

Severe pipeline deterioration

![]()

Project

2nd generation rehabilitation – Severely deteriorated 89″ diameter concrete pipe

![]()

Client

City of Everett, Washington

![]()

Location

89″ diameter pipeline in Everett, Washington

Description

This pipeline had previously been rehabilitated with an epoxy coating. Pinholes in the coating system had allowed sewer gases to continue to attack the host structure, resulting in failure of the coating and further deterioration of the pipe. Pipe has benches or shelves in the bottom forming a channel for the sewage flow.

Solution

Poly-Triplex Certified Installer bridged the flow in the channel with a sub-floor and allowed the sewage to flow underneath, saving the city many thousands of dollars. The liner was then pulled through, inflated with an internal bladder and cured-in-place from waterline to waterline.

Benefit

The Poly-Triplex Liner System incorporates a gas and water impermeable inner membrane that is encapsulated between layers of structural fiberglass. These liner materials are saturated with epoxy and laminated to the interior of the pipe providing a permanent barrier to further deterioration.

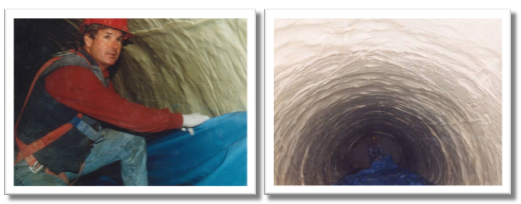

Upper Left: Epoxy has failed due to pinholes in the coating allowing gas penetration to further attack the host structure.

Upper Left: Epoxy has failed due to pinholes in the coating allowing gas penetration to further attack the host structure.

Upper Right: Structure has been thoroughly pressure cleaned and remains of epoxy coating removed. Structure is now prepared for the Poly-Triplex installation.

Upper Left: Poly-Triplex Liner has been cured-in-place using the removable inflation bladder.

Upper Left: Poly-Triplex Liner has been cured-in-place using the removable inflation bladder.

Upper Right: Inflation bladder is removed to reveal a completely monolithic and permanent rehabilitation.

Comments

This pipe was rehabilitated in 11008 and is still working as effectively as it was the day it was installed. There has been no further deterioration.